Authors: Sean Zimmerman-Wall

Uinta Taps Into Local Artists’ Creativity with The Crooked Line

Salt Lake City has become the unlikely location of a meticulously fashioned merger between a vibrant art scene and a competitive craft brewing community. Uinta Brewing has been long revered for its perfectly balanced selection of beers, but now it is tipping the scales with the continuation of its Crooked Line. “The Crooked Line is a blank piece of canvas to make some fun beers with fun names and [work with] fun local artists,” says Uinta president Will Hamill. … read more

The Riders Project: A New Way to Give

Philanthropy is a word that seldom enters the vocabulary of younger generations. It’s not that we don’t care, but between rising gas, tuition and beer prices, there is not much left over after the bills are paid. Enter TheRidersProject.org, a small organization with large aspirations to get young people, especially those active in the outdoors, to donate to worthy causes around the globe. … read more

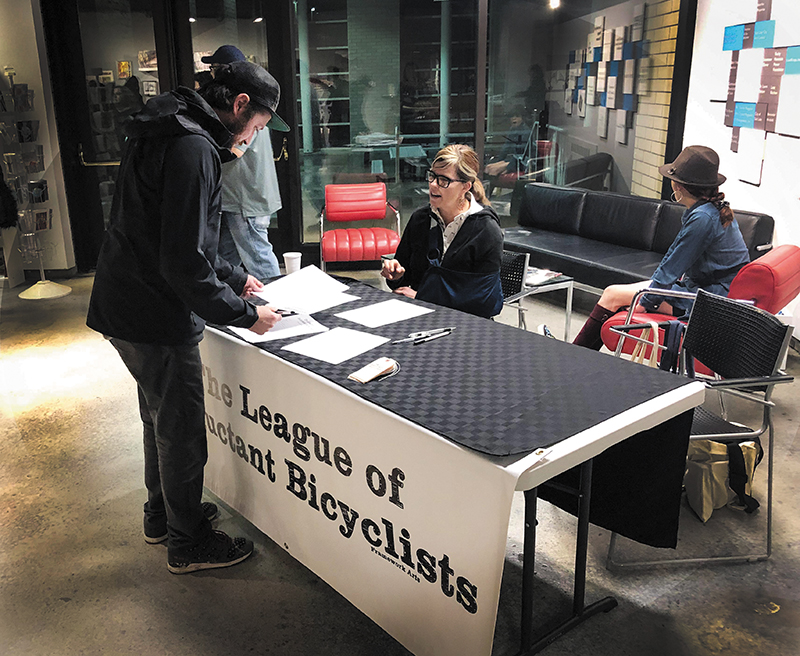

Art in Motion: The League of Reluctant Bicyclists Takes to...

Megan Hallett of Framework Arts has set out on her latest project, The League of Reluctant Bicyclists, slated to become a living exhibit at UMOCA. … read more

Water, Bricks, and Booze – A look at SLC’s Dented...

The history of Dented Brick Distillery reads more like a Western novel rather than the founding of one of Utah’s fastest-growing purveyors of fine spirits. A series of events set in motion over a century ago during the Mormon-pioneer era culminates on a “piece of land that was destined for whiskey.” … read more

Rodrigo y Gabriela @ Red Butte Garden 09.16 w/ Robert...

This dynamic duo, Rodrigo y Gabriela is a force of nature that combines traditional Spanish guitar with pulse-pounding instrumentals inspired by an affection towards heavy metal. … read more

Shaping the Future: An Interview with DPS Founder Stephen Drake

Stephan Drake, founder of DPS Skis, realizes the vast potential of the area, and his dedication to building quality, hand-crafted skis exists to this day. … read more

The WhiSKI Series: High West and TGR Team Up For...

Some things in this world were just meant for each other. You can probably think of a few of your favorites, but one we can all agree on is whiskey and skiing. … read more

Sixth Law Cycles – Building Momentum: A Look at Four...

John Koutrouba discusses his business, Sixth Law Cycles, where he builds bikes that are a bit quirky, using materials that are unusual in the industry. … read more

Saltair Cycles – Building Momentum: A Look at Four Local...

Deemed the “Best New Builder” by the North American Handmade Bicycle Show (NAHBS), Saltair Cycles is excited to continue to build highly functional and aesthetically provocative bikes for customers. … read more

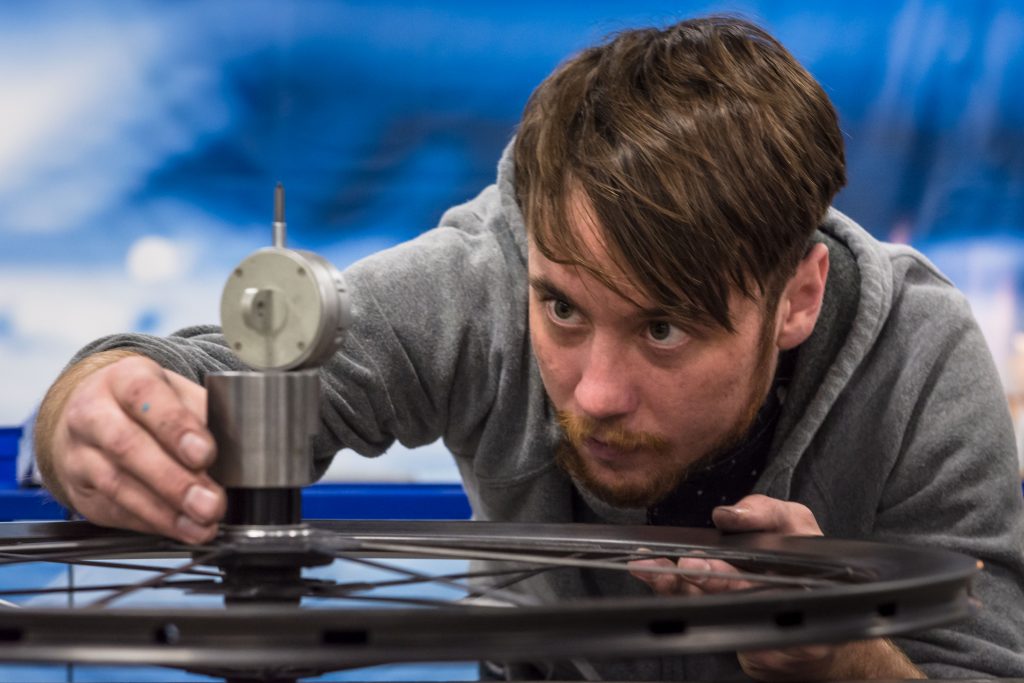

Reynolds Cycling – Building Momentum: A Look at Four Local...

Visit Reynolds Cycling for amazing, technologically advanced bike equipment with quality service for local athletes to everyday cycling aficionados. … read more